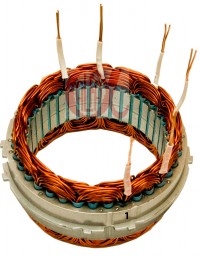

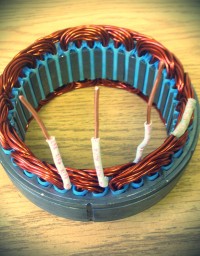

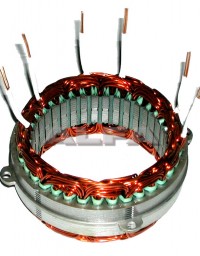

Stators

At ALFA, the stators are wound by an automated wave wind machine. During the machine's operation, the specs of the stator are applied automatically.

1. WIRING

Wire size is gauged to OE specifications and the amount of turns also match the OE specifications. At ALFA, we only use the highest quality of magnetic wire available on the market in order to provide maximum output and longer resistance.

2. INSULATION

Insulators are inserted between the magnetic wire and the stack to isolate the wire from the metal stack, thus avoiding contact between them. This is done by a machine which completes the operation in approximately 25 seconds. Due to the critical conditions, we use thick and high quality insulators in the market.

3. LAMINATION & TESTING

ALFA uses new laminatons for its stators. The varnish used by ALFA is also of the highest quality. As for testing, stators are tested at 1000 volts with zero amp tolerance of leakage comapred to 500V used by the competition. By using 1000V, we eliminate at 99.9% the possibility of any errors on the stators.

We offer R & R (Rebuild & Return) on all our stators, which include domestic, foreign, marine, industrial and agricultural applications